Nanoscale Innovation: The Creation of the World's Smallest 3D Transistor and Its Implications

Introduction

In the ever - advancing realm of nanotechnology, the creation of the world's smallest 3D transistor represents a monumental leap forward. Transistors are the fundamental building blocks of modern electronics, and their continuous miniaturization has been a driving force behind the exponential growth of computing power and the shrinking size of electronic devices. The development of a 3D transistor at the nanoscale not only pushes the boundaries of what is technologically possible but also holds the key to unlocking a new era of high - performance, energy - efficient, and ultra - compact electronics. This article delves into the intricate details of this nanoscale innovation, exploring its fabrication process, unique characteristics, and far - reaching implications across multiple industries.

Understanding Transistors: A Brief Primer

Transistors are semiconductor devices that can amplify or switch electrical signals. They consist of three main terminals: the source, the drain, and the gate. In a traditional planar transistor, these components are arranged on a flat, two - dimensional surface. The flow of electrons between the source and the drain is controlled by the voltage applied to the gate. When a voltage is applied to the gate, it creates an electric field that either allows or restricts the flow of electrons, effectively acting as a switch.

Over the past few decades, the semiconductor industry has been relentlessly focused on reducing the size of transistors. This process, known as Moore's Law, has enabled the packing of more and more transistors onto a single integrated circuit (IC), leading to a corresponding increase in computing power and a decrease in the cost per transistor. However, as transistors approach the physical limits of miniaturization in a planar configuration, new technologies are required to continue this trend.

The Advent of 3D Transistors

The development of 3D transistors represents a significant departure from the traditional planar design. Instead of being laid out flat, 3D transistors are constructed in a vertical, three - dimensional structure. This allows for a more efficient use of space, as multiple transistors can be stacked on top of each other. One of the most well - known examples of a 3D transistor is the Fin - Field - Effect Transistor (FinFET).

FinFET Technology

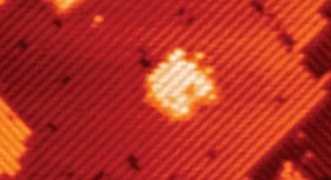

FinFETs were first introduced by researchers at the University of California, Berkeley in the 1990s. The key feature of a FinFET is its fin - like structure, which extends vertically from the substrate. The fin serves as the channel through which electrons flow between the source and the drain. The gate is wrapped around the fin, providing better control over the electron flow compared to a traditional planar transistor. This improved gate control allows FinFETs to operate at lower voltages, reducing power consumption while maintaining high performance.

The world's smallest 3D transistor takes the concept of FinFETs to the next level, pushing the boundaries of nanoscale fabrication. By reducing the dimensions of the fin and the overall transistor structure to the nanometer scale, researchers have been able to achieve unprecedented levels of miniaturization and performance.

Fabrication of the World's Smallest 3D Transistor

The fabrication of the world's smallest 3D transistor is a highly complex and precise process that requires state - of - the - art nanolithography techniques. Nanolithography is the process of creating patterns on a substrate at the nanoscale. There are several techniques used in nanolithography, including electron - beam lithography, extreme ultraviolet (EUV) lithography, and self - assembly methods.

Electron - Beam Lithography

Electron - beam lithography is a high - resolution technique that uses a focused beam of electrons to expose a resist material on the substrate. The resist material is then developed, leaving behind a pattern that can be used to define the structure of the transistor. Electron - beam lithography offers extremely high resolution, allowing for the creation of features as small as a few nanometers. However, it is a relatively slow and expensive process, making it more suitable for research and development applications.

Extreme Ultraviolet (EUV) Lithography

EUV lithography is a more advanced and high - volume manufacturing technique. It uses light in the extreme ultraviolet range to expose the resist material. EUV lithography has a much shorter wavelength than traditional optical lithography, enabling the creation of smaller and more precise patterns. This makes it an ideal technique for the mass production of nanoscale transistors. However, EUV lithography is also a very complex and costly technology, requiring significant investment in equipment and infrastructure.

Self - Assembly Methods

Self - assembly methods are another approach to nanoscale fabrication. These methods rely on the natural tendency of molecules or nanoparticles to arrange themselves into ordered structures. In the context of transistor fabrication, self - assembly can be used to create the fin structure or other components of the 3D transistor. Self - assembly methods offer the potential for low - cost, high - throughput fabrication, but they also present challenges in terms of controlling the precise structure and properties of the resulting components.

Characteristics and Performance of the Smallest 3D Transistor

The world's smallest 3D transistor exhibits several unique characteristics and performance advantages over traditional planar transistors.

Ultra - High Density

The 3D structure of the transistor allows for a much higher packing density compared to planar transistors. By stacking multiple transistors on top of each other, more transistors can be integrated onto a single IC, leading to a significant increase in computing power. This ultra - high density is crucial for applications such as high - performance computing, artificial intelligence, and data centers, where the demand for processing power is constantly growing.

Improved Gate Control

The fin - like structure of the 3D transistor provides better gate control over the electron flow. The gate is wrapped around the fin, which increases the surface area in contact with the channel. This allows for more precise control of the transistor's on - and - off states, reducing the leakage current and improving the overall performance and energy efficiency of the transistor.

Low Power Consumption

As mentioned earlier, the improved gate control of the 3D transistor enables it to operate at lower voltages. This results in a significant reduction in power consumption, making it an ideal choice for battery - powered devices such as smartphones, tablets, and wearable electronics. In addition, the lower power consumption also helps to reduce the heat generated by the transistor, which is a major challenge in high - density ICs.

High - Speed Operation

The small size and improved performance of the world's smallest 3D transistor also enable high - speed operation. The reduced dimensions of the transistor result in shorter electron travel distances, which in turn reduces the signal propagation delay. This makes the transistor suitable for applications that require high - speed data processing, such as 5G communication, high - definition video streaming, and real - time data analytics.

Implications Across Industries

Computing

In the computing industry, the development of the world's smallest 3D transistor has the potential to revolutionize the performance of CPUs and GPUs. The higher packing density and improved performance of these transistors will enable the creation of more powerful and energy - efficient processors. This will lead to faster computers, better gaming experiences, and more advanced artificial intelligence and machine learning applications. In addition, the reduced power consumption of the transistors will also help to extend the battery life of laptops and other portable computing devices.

Mobile Devices

For mobile devices, the smallest 3D transistors are a game - changer. Smartphones and tablets are constantly evolving, with users demanding more features, better performance, and longer battery life. The high - density and low - power characteristics of these transistors allow for the integration of more powerful processors and other components into a smaller form factor. This means that future mobile devices will be able to offer faster speeds, better graphics, and more advanced functionality without sacrificing battery life or size.

Internet of Things (IoT)

The IoT is a rapidly growing ecosystem of connected devices that includes everything from smart home appliances to industrial sensors. The world's smallest 3D transistors are well - suited for IoT applications due to their low power consumption and small size. IoT devices often operate on battery power and need to be small and compact to be easily integrated into various environments. The high - density transistors enable the development of more powerful and feature - rich IoT devices that can communicate with each other and with the cloud more efficiently.

Healthcare

In the healthcare industry, the development of the smallest 3D transistors has several implications. For example, in wearable health monitors, these transistors can be used to power more advanced sensors that can accurately monitor vital signs such as heart rate, blood pressure, and glucose levels. The low power consumption of the transistors ensures that these devices can operate for long periods of time on a single battery charge. In addition, the small size of the transistors allows for the creation of more compact and unobtrusive wearable devices. In the field of medical imaging, the high - speed operation of the transistors can potentially lead to faster and more accurate imaging technologies.

Automotive

The automotive industry is also set to benefit from the world's smallest 3D transistors. In electric vehicles (EVs), power efficiency is crucial. The low - power transistors can be used in the vehicle's battery management system, motor control units, and other electronics, reducing the overall power consumption and extending the driving range of the EV. In addition, the high - density transistors can enable the development of more advanced driver - assistance systems (ADAS) and in - vehicle infotainment systems, providing a more seamless and intelligent driving experience.

Challenges and Future Outlook

Despite the many advantages of the world's smallest 3D transistors, there are also several challenges that need to be addressed. One of the main challenges is the cost of fabrication. The advanced nanolithography techniques required to manufacture these transistors are extremely expensive, which may limit their widespread adoption in the short term. However, as the technology matures and economies of scale come into play, the cost is expected to decrease.

Another challenge is the reliability of the transistors. As the size of the transistors decreases, the effects of quantum mechanics become more significant, which can lead to issues such as increased noise and instability. Researchers are working on developing new materials and design techniques to mitigate these problems and ensure the long - term reliability of the transistors.

Looking to the future, the development of even smaller and more advanced 3D transistors is likely to continue. As the demand for high - performance, energy - efficient electronics grows across various industries, there will be a constant push to improve the performance and capabilities of transistors. In addition, the integration of other emerging technologies, such as quantum computing and artificial intelligence, with 3D transistor technology may lead to the creation of entirely new classes of electronic devices.

In conclusion, the creation of the world's smallest 3D transistor is a significant milestone in the field of nanotechnology and electronics. Its unique characteristics and performance advantages have the potential to revolutionize multiple industries, from computing and mobile devices to healthcare and automotive. While there are challenges to overcome, the future looks bright for this exciting technology, and we can expect to see its impact on our lives in the years to come.